The Spinning Mill

The Spinning Mill

Carding and Combing

The fibers are first brought in one direction to then comb out any vegetation residue along with harder wool fibers. Only clean and strong fibers remain. This technique gives us eco-friendly yarn that is more elastic, longer lasting and softer than yarn made from traditional sulfuric acid-treated wool.

Dyeing Process

To make white wool blue, we leave out metal complex dyes. Our dyeing process is environmentally certified and is therefore regularly audited in all safety standards by environmental organizations and trade unions. The in-house sewage treatment plant ensures only pure water gets out or the mill.

Spinning a Yarn

The heart of yarn production is spinning. The strong-yet-fine wool fibers of our sheep are especially suited to machine processing. Their extremely high quality allows us to produce a durable and smooth yarn — which ultimately results in a very cozy and warm sweater.

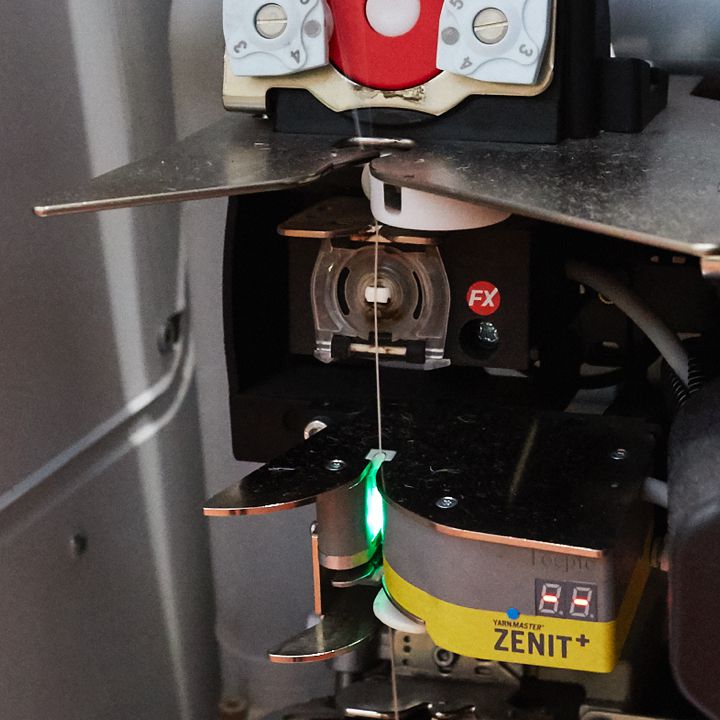

Quality Control

With the help of the latest laser technology, every millimeter of our yarn gets thoroughly inspected and even the smallest knots and imperfections are removed. The result? An especially high-quality wool yarn for your pullover.